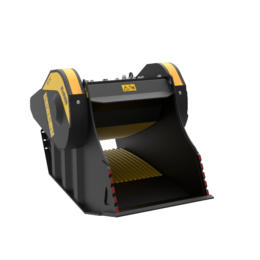

NEW BUSINESS WITH THE MB CRUSHER BUCKET - an interview in Lebanon

Thanks to its dealer in Lebanon, AMTRAC ABDELMASSIH TRADING CO., MB Crusher collected two very interesting interview with some customers that are using the MB crusher bucket in their yard.

Mr. SJK Sassin and Jihad Kaii founded their company in 1997, a company involved in excavation and asphalt and bitumen works. They have more or less 40 machines and 45 employees. The first time they heard about MB crusher bucket was because they were invited to a demonstration by Amtrac Company.

Why did they choose to buy the MB Crusher bucket? The answer is very simple! "A license for a traditional crusher machine is very hard to get, you need connection and lot of money to use it...on the contrary MB crusher bucker is a very convenient machine."

But there're also other very important reason why they chose MB: "In the past we had to pay to dump excavated products in landfills. And then we had to buy base course for asphalt and road construction project. Now, with the MB crusher bucket, we are doing the entire processing by ourselves. Currently we're using MB attachment 8 hours of work 5 days per week. We are crushing our own base course and we can choose between different ranges of output for our road construction".

"Moreover I can say that MB crusher bucket it's a very convenient machine for our business because having a traditional machine for our size is not justified, plus it is very hard to get a traditional crushing tool. We had an old machine that we were planning to reject and replace. However, instead of rejecting it, we invested in MB crusher and now we are keeping to do the job. No need for excavator to travel, it is positioned efficiently.

Finally the operator is very happy with the machine. It does not vibrate the machine like a hydraulic breaker, no problems at all so far."

Also Cheaitly family, owner of Al Israa Company, is very happy about its MB crusher bucket.

Al Israa is reknown contractors in the South of Lebanon. They're dealing with excavation, they own an asphalt plant and they are involved in road construction activities, operating with more than 15 machines.

They first heard about MB crusher bucket through the dealer AMTRAC.

"Having a crushing plant is hard and sometimes crushing plants are not allowed to work. However, MB provided us with a great and feasible solution. It helps a lot in our work and the operator can at the same time crush the material and fill the truck.

We own a BF70.2, it is very useful even though small. We are considering a bigger size, but for the moment its doing the job perfectly. We are using 5 bars on the MB to get fine particles to be used as base course; base course that can be used on both 1st and 2nd layer.

MB crusher bucket is producing on average 6 trucks(20m3/each) per day, working 8hours/day, 6 days/week. The material that has been crusher is sourced from excavation on different locations resulting from the work of a hydraulic breaker. We're currently is crushing excavated material into base course. So, instead of paying landfills to dump material, they can now crush it and use it as base course... so it is a cycle! "

I can say that our MB crusher bucket is operating for 4 month now, we had no problem faced., it's a very great machine!